Bioethanol Over Production from Second Generation Feedstock using Rice Straw as Lignocellulosic Waste

DOI:

https://doi.org/10.5530/ctbp.2021.6.4Keywords:

Lignocellulosic biomass, fermentable sugars, Saccharomyces cerevisiae, Fermentation, BioethanolAbstract

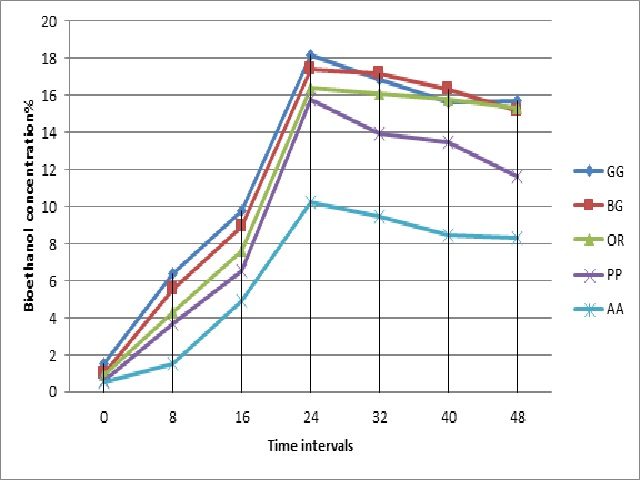

The efficient conversion of lignocellulosic biomass to fermentable sugars has shown several environmental and economic advantages in the ethanol production technology as compared to the bioethanol produced from food crops. In this study, rice straw which is a complete waste and which when burning give rise to pollution was used as the substrate. In this present investigation, the rice straw was pretreated with various physical (chipping, milling, grinding) and chemical (acid, alkali) methods to reduce the crystallinity content and remove lignin. A combination treatment of grinding along with 4% NaOH was found to be the most effective one. The production of bioethanol was carried out by using rice straw as a feedstock and by taking Saccharomyces cerevisiae as a fermentative microorganism. Yeasts were isolated from different food sources and were identified and selected based on the cell morphology, biochemical characterization, and ethanol tolerance capability. The potential isolates underwent enzyme saccharification by adding the cellulase enzyme followed by fermentation. Cultural conditions optimization was maintained by incubating the isolates for a period of two days. Also, the effect of temperature and pH on bioethanol production was checked at various ranges. In this investigation, the optimum parameters found for bioethanol production was an incubation time of 24 hrs, keeping the temperature and pH at 30°C and 4.5 respectively. After a week of fermentation, ethanol was obtained. For determining the ethanol concentration, the potassium dichromate method was used. The yeasts isolated from green and black grapes were found to synthesize a higher concentration of bioethanol. The highest yield of ethanol obtained in this study was found to be 18.2%.